Ipe Oil. Best Product to Protect your Ipe Decking

Ipe Oil is specifically designed to protect the Ipe Decking. It is an oil based product that protects Ipe from discoloration due to UV exposure. For best results, apply Ipe Oil to both sides of the Ipe boards during installation. What contractors typically do is they apply the Oil to the underside of the deck boards prior to the installation (as it will no longer be accessible in some cases) and they apply the top coat after the installation. Ipe Oil should be applied with a deck staining brush. We recommend the Pedura Deck Boss Brush.

It is best to apply the Ipe Oil when the temperatures are above 10 degrees celsius and no rain for 48 hours.

For older Ipe Decks, it is best to pressure wash them prior to the application of Ipe Oil. A Deck Cleaning product, such as Deck Pro Clean by Cutek can be used to chemically remove stains and dark spots from the Ipe decking. If the deck is very old and has not been oiled in several year and you want to bring back its natural color, we recommend sanding the Ipe deck. The beauty of Ipe decking is that it will not crack/deform much even if left untreated and you can always bring back its original color, after many years of not doing maintenance, just by sending it.

Ipe Clips. Hidden Fastener Clips for Ipe Decking.

Ipe Clips are specifically designed to go with our pre-grooved 5/4×6 or 1×6 grooved decking. Ipe Clips are designed to hold Ipe well to the wood framing. The screw goes through the Ipe board (at an angle) and into the joist. The holes in the Ipe need to be pre-drilled prior to installing the screw. Each package of Ipe clips comes with stainless steel screws, drill bits, Ipe clips and a few plugs for the first starter board. The Ipe clips themselves are made of stainless steel material coated with plastic. Ipe clips also provide perfect 1/8″ or 5/32″ spacing between the Ipe boards. Each clip has a short stem that helps space the boards evenly. Ipe clips are also faster to install than surface screwing deck boards as one only needs to attach the clips on one side of the board, the next board slides into the the clip. Installing your Ipe decking with Ipe clips ensures you have a fastener free surface and well attached Ipe decking.

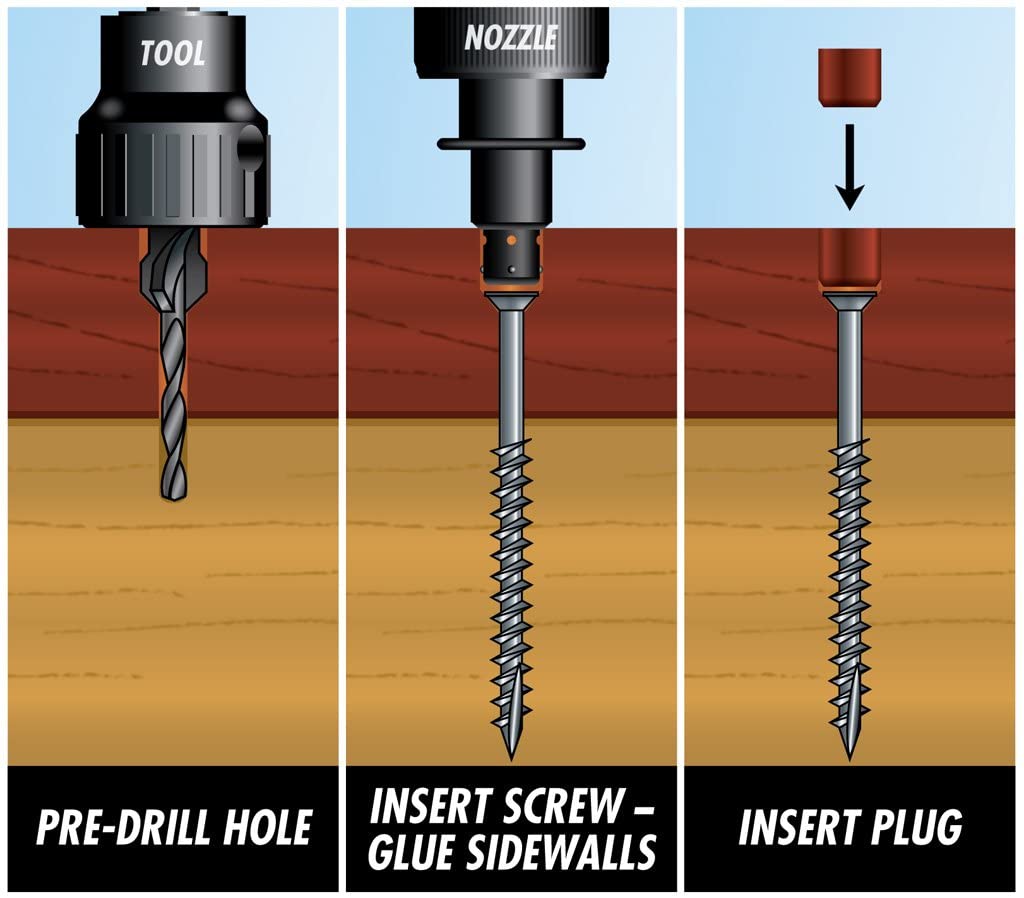

Ipe Plugs. Ipe Screw and Plug system.

Starborn manufacturer has an excellent screw and plug system for Ipe fencing and screen boards. If you are not able to use grooved boards for your particular application – then we recommend attaching your Ipe boards with screws and plugs. The pro plug system comes with Ipe plugs, stainless steel screws and a pre-drilling tool that allows the installer to pre-drill a hole for the screw and make a perfectly sized opening for the plug in one move. The plugs do not need to be cut to size after by being trimmed, the pre-drilling tools ensures that each plug fits perfectly into the hole.

Each Package comes with 2 1/2″ long screws and covers approximately 100 sq. ft. If you need fewer screws, we also offer Ipe Plugs by Deck Wise. These plugs are cheaper and one can use a typical 3/8″ drill bit to pre-drill for these plugs, but these plugs need to be cut off with a flush saw after installation for a smooth, level top surface.

Trim Screws. Stainless steel, color matched.

Another way to attach the Ipe boards to framing is by using trim head color matched screws. This method is faster and cheaper than using screws and plugs. Trim head screws come in various lengths and the screw heads are fairly small, designed to fit a T15 torx driver screw bit. You still need to pre-drill for these screws with a 1/8″ drill bit and for best results, you can also pre-drill with a 3/16″ drill bit to countersink a screw head. For most clients, a small screw head that is color matched to the Ipe decking is a perfectly acceptable fastening method. These screws are stainless steel so they will not leave any marks on the Ipe wood.

End Seal. Wax to treat cut edges of Ipe decking.

When Ipe deck boards are shipped from Brazil, they have all of their edges sealed with a wax. When this edge is cut on site it is best to seal it with End Wax seal. This wax prevent the deck boards from cracking on the edges. When applying the wax, it is important to keep it the wax on the edges only, if it ends up being on the surface, it will stand out from the rest of the board.

Bison Pedestals. Adjustable Height pedestals for Ipe Tiles and 2x4 Frame Rooftop Decking.

These pedestals are an excellent product to compliment Ipe Tiles. They are adjustable in height and offer pedestal options from 1/8″ to over 24″ in height. The Ipe tiles have grooves cut in the corners that fit into the Bison pedestals. Given that all flat roofs have a slope, being able to adjust your pedestal to the desired height during installation saves on the installation time. Ipe Wood offers the full line of Bison products including plastic and rubber shims. Apart from Ipe Tiles, these pedestals also work well with outdoor porcelain tiles. Many clients prefer a combination of stone and wood on their terraces and Ipe decking combines well with porcelain.